2、在检修汇流箱时,养成习惯性的将所有螺丝紧固一遍,在紧固螺丝时一定要注意安全,避免手同时触碰到正负极接线端,或者同时触碰到正极和PE线或者负极和PE线。

The combiner box is a product connecting the past and the future in the photovoltaic power generation system. There is a photovoltaic cell array in the front and an inverter in the rear, so it is a very important product. Because the working conditions

are outdoor, it has been attacked by rain and snow for a long time, and the working environment is very harsh.

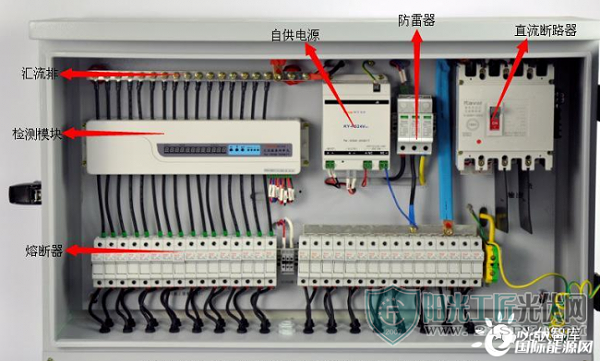

Taking the DC combiner box as an example, it is mainly reflected in: in addition to the main functions of

combiner and lightning protection, it also adds the collection of voltage, current and temperature, monitoring of working status, imbalance and failure alarm, data and transmission, etc.

The service life of photovoltaic power stations

is set as 25 years by power generation enterprises. There is no unified standard in the industry whether the components can withstand the test in its full life cycle.

In order to master the operation status of PV module equipment,

timely discover and eliminate equipment defects, prevent accidents, and ensure the completion of power generation plan, equipment patrol inspection shall be carefully carried out.

1. Check that all components of DC combiner

box are normal without deformation, and installed firmly without looseness.

2. Check that the appearance of DC combiner box is clean without dust, the equipment label is free from falling off, and the equipment label is clear and

accurate.

3. Check that the DC combiner box lock is in good condition and has good sealing.

4. When the DC combiner box operates normally, all fuses are put into operation, the acquisition board operates normally,

and all lightning arresters and switches are put into operation.

5. Check that all components are free of abnormal phenomena such as overheating, odor and disconnection, and that all electrical components are in the state required

for operation.

6. The operation indicator of the power module of the acquisition board is on, and all components are normal.

7. The lightning protection module has no breakdown.

8. The

fuse of each branch shall be free from obvious rupture.

9. Check that the DC switch of the DC combiner box is configured correctly, there is no disconnection, and the protection setting is correct.

10. Check

that the indication of the data collector is normal, and the signal display is consistent with the actual working condition.

11. The grounding wire of DC combiner box is reliably connected; The fracture and falling off shall be

reported to the shift supervisor on duty in time and handled.

12. Check that the incoming and outgoing cables of the DC combiner box are intact without discoloration, falling, looseness or disconnection.

Precautions

for maintenance of combiner box:

1. When overhauling a branch of the combiner box, the circuit breaker must be disconnected first, then the fuse box of the branch to be overhauled, and then the circuit breaker must be

closed before overhauling the collector line. Remember not to pull out the M4 plug without disconnecting the DC circuit breaker, nor open the fuse box without disconnecting the DC circuit breaker, so as to avoid personal safety accidents.

2. When inspecting and repairing the combiner box, make it a habit to tighten all the screws. Pay attention to safety when tightening the screws to avoid touching the positive and negative terminals at the same time, or touching the positive and

PE wires or the negative and PE wires at the same time.

报错 笔记